Congratulations Team Irving Vincent

Hardman Bros would like to congratulate Team Irving Vincent on there stunning performance at the Australasian Superbike Championship, claiming the Pro Twins class title.

uPrint SE Plus 3D Printer

Hardman Bros. have received (and tested) their latest piece of machinery, a 3D printer that will hasten the design and testing process.

AUSTECH 2009

In May, Hardman Bros., together with R & I Instrument & Gear Co., exhibited at Australia's premier engineering expo, AUSTECH. Held at Melbourne Convention and Exhibition Centre in the Southbank region of Melbourne, it provided a valuable opportunity to meet with existing and

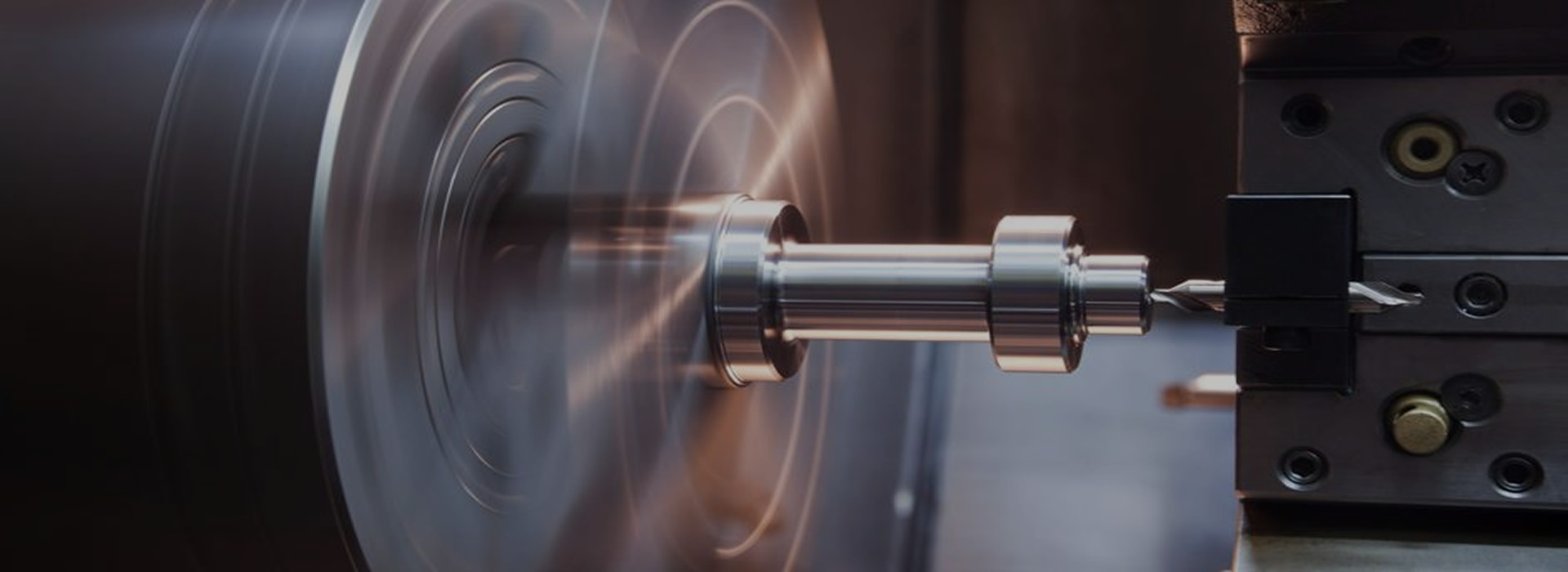

VT1150 High Performance Vertical CNC Lathe

On 19th July 2011 - Hardman Bros. commissioned the new VT1150 High Performance Vertical CNC Lathe with live tooling. This state of the art machine uses the advanced Fanuc controller with full conversational & 'G' code programing with the addition of Glass Scale